1. Introduction

Yellowtail kingfish also known as Goldstriped amberjack, Hiramasa and by its scientific name Seriola lalandi is a circumpolar species, distributed naturally only in the Southern Hemisphere, particularly in the coastal waters of Australia, New Zealand, South America and in the Indian ocean.

Seriola species, which includes Yellowtail Kingfish, Great Amberjack, and Hamachi, have excellent market potential as it is a highly regarded fish for consumption, not just as a favored choice for sashimi/sushi, but for seafood cuisine in general.

Yellowtail Kingfish, also called Hiramasa, is second only to tuna as the most appreciated fish for sashimi/sushi. Unfortunately, Kingfish is not widely available in European markets, with the majority of the product being consumed in Japan. In addition, the majority of Seriola produced worldwide (including: Seriola quinqueradiata, Seriola dumerili and Seriola lalandi) is from Japan (approx. 140,000 tons per year).

Dr. Bent Urup has played a key role in the design and technology supply of several hatcheries around the world that are now producing juvenile Kingfish. These facilities utilize technology that originated from and was created and developed by Dr. Bent Urup during his PhD. It was initially applied to produce Turbot juveniles, and then optimized and adjusted over the years for Kingfish production.

The largest hatcheries for Kingfish production outside Japan are located in Australia (Clean Seas), Chile (Acuinor), Saudi Arabia (NPC), and Denmark (Maximus A/S). Dr. Bent Urup has been involved in the design and the technology delivery of all these hatcheries.

2. Key notes for when considering farming of Kingfish

- In General:

i. Kingfish market price is substantially higher than the price of Atlantic Salmon. The European market may initially be limited, despite the global recognition of kingfish as one of the best seafood products. This limited awareness in Europe may be attributed to its low availability, except perhaps in Spain and Italy.

ii. The feed for kingfish has a higher content of protein and generally relies on fish meal and oil as principal ingredients. This makes the feed more expensive.

iii. When farmed in sea cages, the higher protein content of the feed increases the eco-pollution footprint as nitrogen and phosphors discharge are closely related to feed protein content.

iv. Seriola lalandi is not naturally found in European waters, so it's expected that farming it will likely only be permitted in RAS facilities.

v. Yellowtail kingfish are highly susceptible to ectoparasites, which presents significant challenges when farming them in cages. One option is to remove and clean all the nets at regular intervals, but this is expensive. Another option is to treat the fish with chemicals, but this has a negative impact on the marine ecosystem surrounding the cages. In countries like Australia, where the marine environment is highly valued, net cleaning is the only viable option despite the high cost.

vi. Brood stocks for Kingfish are now established in Europe, in Holland and Denmark. Spawning has been demonstrated to be easily controllable within the brood stock systems designed by Aqua-Partners ApS/ Dr. Bent Urup. These installations utilizing Dr. Bent Urup technologies are consistently generating a year-round supply of eggs at a relatively low cost.

vii. The production of 1-gram post-hatch kingfish from eggs is relatively complicated, and access to juveniles is generally the critical point in production.

viii. The biggest hatcheries for Kingfish production are currently located in Australia and Chile, both based on designs developed by Dr. Bent Urup, delivered by UNI-Aqua A/S.

ix. Kingfish production is new in aquaculture, but quickly proved to be naturally suited for domestication. Kingfish is not shy; in fact, it displays quite the opposite behavior. It is a highly aggressive feeder, which simplifies feeding practices and ensures efficient feed assimilation to saturation for all individuals.

x. The fish is very tolerant to salinity and performs well within the range of 12 - 40 ppt.

xi. It is crucial to maintain the temperature above 19°C throughout the farming period to prevent maturation of the fish. Ideally, the production temperature should consistently remain above 22°C, with 24°C, at present, being considered the optimal temperature.

- In relation to RAS farming of Yellowtail Kingfish:

i. Based on our present knowledge, a high production temperature during growout, likely around 24°C, is optimal for a RAS facility since biofilters perform better at higher temperatures in general. In the case of kingfish production, it compensates for the higher protein content in the feed, which by nature increases the demand of biofilter capacity within the Ras installation. Thus, even if the feed has a higher content of protein, the biofilter requirement per ton production is almost the same as for Steelhead salmon production.

ii. RAS farming yields a higher fillet percentage of over 60%, compared to wild fish which is only around 40%.

iii. Kingfish growth manages very well a high-density production in RAS installations. Obviously, this hinges on the assurance that water supply and quality meet the optimal requirements. Maximum densities for kingfish production, ensuring that both growth and welfare needs are met without compromise, can still be investigated. However, it is evident that these densities far exceed 100 kg/m3, and likely beyond 200 kg/m3 as well (in growout stages).

iv. Even slight fluctuations in temperature can negatively affect the growth and feed conversion of yellowtail kingfish. This issue can be mitigated by using recirculating aquaculture systems (RAS) which provide more stable environmental conditions for the fish.

v. Kingfish have proven to perform very well in RAS facilities. It takes 12 months to go from fry to harvest, with Kingfish reaching a weight of 4.5 kg from an initial weight of 10 grams.

vi. When farmed in RAS with appropriate temperature and water quality, Kingfish can grow very fast. There are examples of individuals reaching a weight of approximately 900g in just 5 months after hatching. Even if these cases are far from average growth, this indicates the potential in doing genetic selection specifically for farming the fish under constant temperature in RAS.

vii. Growth performance is expected to improve further through domestication and genetic selection. Within 3-4 generations, by structured genetic selection, one might gain an increase in growth rate in the range of 50%.

viii. Due to the high temperature, it is of key importance that the RAS facility is designed for securing low total ammonia levels as well as low CO2 levels. Otherwise, the fish will not perform to their potential.

ix. With advanced RAS technology in combination with wastewater treatment technology, Kingfish can be produced without causing the environmental problems associated with cage farming. This presents an opportunity to expand Kingfish production beyond the limitations set by suitable sites for cage farming.

x. In Ras farms the fish can be produced 100 % free of parasites. In this regard, it might be possible to develop a premium fish for the sushi market.

xi. Access to juvenile yellowtail kingfish and suitable farming sites are limiting issues.

3. Farming: Production stages of Kingfish

i. Broodstock: https://youtu.be/_euE4kLQOUM

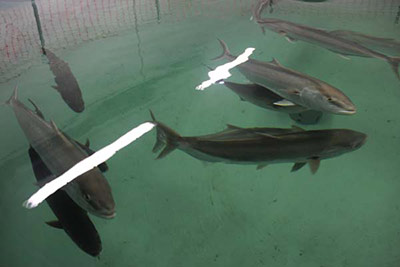

Yellowtail Kingfish broodstock, behavior in Ras tank, (video and picture at Acuinor from Bent Urup)

ii. Fry:

iii. Juvenile:https://youtu.be/gTmW_VEzMCc

Yellowtail Kingfish juvenile, behavior in Ras tank, (video at Acuinor from Bent Urup)

iv. Kingfish are growing very fast with the right temperature regime and water quality, the individual on the picture below does not represent the average growth but indicates the potential of the fish when being farmed in RAS, with a weight of approx. 900 g 5 months post hatch:

Picture of a fast grower Kingfish that reached 900 gram in April 2011, from a batch of eggs spawned in December 2010 (picture taken in Acuinor farm).