1. Introduction

Bluefin tuna (Thunnus thynnus) is a species of fish highly valued for its rich and tender texture, making it a delicacy in many parts of the world. However, overfishing has led to a decline in wild populations, causing the market value of Bluefin tuna to skyrocket. As a result, the species has become a potential candidate for aquaculture production as a means of reducing pressure on wild populations.

Farming any Tuna species necessitates overcoming numerous challenges as it is one of the most complicated species groups to produce. Especially the complexity of the reproduction stages, which is considered as a key milestone in marine aquaculture. However, despite many advancements, it's crucial to acknowledge that tuna farming, especially Bluefin tuna, may never achieve long-term sustainability.

The Bluefin tuna is a highly dynamic fish, capable of maintaining body temperatures above that of their surrounding environment. This characteristic partly explains why the feed conversion efficiency of Bluefin tuna is notably lower compared to most other fish species. For instance, to produce a kilo of Tuna meat, it takes roughly 4 times more feed compared to the production of a kilo of salmon or Kingfish.

Therefore, even though the reproduction of tuna due to the complexity might be seen as the holy grail within fish farming, the development of this industry does not have a bright future.

In the pursuit of a more sustainable tuna species, Yellowfin tuna emerges as a potential viable option. Yellowfin tuna can be farmed at temperatures around 27 °C, eliminating the need for the fish to elevate their body temperature. Consequently, it is foreseeable that Yellowfin tuna production could be significantly more sustainable compared to Bluefin tuna production.

https://www.youtube.com/watch?v=uDljfE4WYOc&ab_channel=Aqua-Partners

Bent Urup has been heavily involved in the successful propagation of Bluefin tuna, which is a highly fascinating species. The brood stock and hatchery technologies developed by Dr. Bent Urup have played a significant role in the technological advancements for tuna production. The ability to produce parasite free copepods is an essential tool for overcoming the challenges encountered during the early larvae stages of tuna.

Clean Seas has also been instrumental in driving the development of tuna production, with Hagen Stehr's vision to produce fry as an alternative to catching young tuna in the wild to supply cages. Hagen Stehr chose to use RAS (recirculating aquaculture system) technology for the broodstock facility and a feeding strategy in the hatchery that does not rely on copepods. The Brood stock facility build near Port Lincon in Australia, with technology designed and delivered by UNI-Aqua A/S, was the first to make Bluefin Tuna spawn in captivity. By manipulating temperature, light and water chemistry, the fish were made to believe they were migrating from south of Australia to the natural spawning grounds south of Java, Indonesia.

https://www.youtube.com/watch?v=I6n3kVELxNI

2. Key notes for when considering Tuna

i. Juvenile production is a complex process, necessitating a supply of various stages of copepods during the initial 10-12 days from when the larvae start feeding. Then onwards up to weaning (transition to a diet of dry pellets), an additional supply of live fish larvae, like newly hatched kingfish or tuna larvae, will be required to feed the tuna fry.

Producing tuna fry without using copepods may be possible in the future, but it could take years to overcome the issues during the early feeding stages. Copepods are the natural diet for tuna larvae, and producing fry on alternative live feed products, such as Artemia and rotifers, may cause malnutrition. Therefore, it is essential to address this challenge to ensure the successful production of tuna fry without the use of copepods.

ii. Investments in broodstock facilities for tuna aquaculture far exceed those for other species. A broodstock tank for Kingfish typically requires a volume of approximately 100 m3, whereas a broodstock tank for Bluefin tuna should ideally be in the range of 2500 m3. Consequently, the water treatment systems and buildings required for Bluefin tuna broodstock facilities are substantially larger.

iii. To produce a kilogram of high-quality Bluefin tuna, it typically requires the equivalent of 20-25 kilograms of herrings. This is 4-5 times more than what is needed for the production of alternative species.

iv. The high costs associated with producing Bluefin tuna in closed, land-based systems make it an impractical and expensive option. Consequently, sea cages emerge as the more viable choice. However, from both sustainability and environmental perspectives, the production of Bluefin tuna appears to be an unsustainable option.

v. Yellowfin tuna appears to be a more viable option. Compared to Bluefin tuna, the reproduction cycle is easier to deal with, juvenile production is similar and requires copepod technology, the feed conversion is much better, and the fish can be farmed in smaller production volumes. Land based farming also appears to be a potential achievable option for the farming of all life stages of Yellowfin tuna. However, the main advantage of Bluefin tuna over Yellowfin tuna is a greater market value.

In conclusion, bluefin tuna has an extremely poor feed conversion rate, requiring approximately 20kg of fish feed to produce just one kilo of the species. This makes it difficult to cultivate Bluefin tuna sustainably. As a result, Yellowfin tuna (Thunnus albacares) may have greater long-term commercial potential due to its ability to be farmed in land-based RAS facilities, where the environment is controlled, and feed conversion can be better managed. This could help to reduce the environmental impact of tuna farming and make it a more sustainable practice.However, more research are required for Yellowfin tuna.

3.Farming: Production stages of Tuna

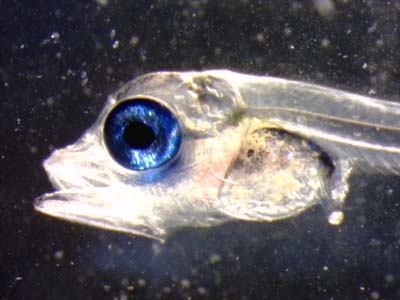

i. The Blue fin tuna larvae hatch around two days after spawning, below are images following the larval development of tuna from pos-spawning to fry (from 2012, where Aqua-Partners was contracted to manage the production during start-up of the facility):

Tuna eggs, 14 hours post spawning. (Picture from Bent Urup)

Bluefin Tuna eggs, 30 hours post spawning. (Picture from Bent Urup)

Bluefin Tuna larvae, day 1 post hatch (Picture from Bent Urup)

Bluefin Tuna larvae, day 2 post hatch (Picture from Bent Urup)

Bluefin Tuna larvae, day 3 post hatch (Picture from Bent Urup)

Tuna larvae, (Picture from Bent Urup)

ii. Below is video highlighting Bluefin Tuna fry active and fast swimming behavior within a rearing tank.

Bluefin Tuna fry fast swimming behavior, Video taken by Dr. Bent Urup while working at Futuna Blue, Spain

iii. Below are pictures following the development of Yellowfin tuna larvae fed on copepods. Tuna workshop in Panama, June 2010, including 3 nations, Australia, United States and Denmark. Luke Cheviot (AUS), Luke Vanderberg (AUS), Polly Hilder (AUS), Dr. Bent Urup (Denmark), Dr. Daniel Benetti (USA), Zack Daugherty (USA), John Stiglitz (USA, Dr. Gavin Partridge (USA/AUS), Vernon Scholey (USA)tuna larvae fed on copepods. Day 1, day 5 and day 15:

Yellowfin Tuna larvae, day 1 post hatch (Picture from Gavin Partridge)

Yellowfin Tuna larvae, day 5 post hatch (Picture from Gavin Partridge)

Yellowfin Tuna larvae, day 15 post hatch (Picture from Gavin Partridge)

iv. The best Bluefin Tuna fry development on a weaning diet, post feeding on copepods was achieved by using an experimental dry pellet developed by Skretting where weaning was obtained as early as day 16 post hatched. (2012, Futuna Blue, Spain, Dr. Bent Urup).

Bluefin Tuna fry, Day 23 post hatch, feeding behavior responses on experimental dry feed pellet from Skretting (video from Bent Urup)

Dr. Bent Urup interview at Futuna blue regarding his alternative feeds experiments on the Bluefin Tuna start feeding stage.

v. It is worth mentioning that in the past, farmers who were trying to produce Bluefin Tuna fry were using Artemia and Rotifer as a start feeding diet. However, these live feeds are not the natural diet of Bluefin tuna as their fatty acid composition is not optimal for the well development of the fry. Dr. Bent Urup has been a pioneer in the development of the technology around the copepod (live feed) production and assimilation to the early stages of Marine fishes. Copepods, regarding Bluefin Tuna, are part of, and if not the main natural diet of this species during the development stage from larvae into a fish fry. Therefore, the best fry development was achieved using copepods.

Dr. Bent Urup interview at Futuna blue regarding copepods as live feed on the Bluefin Tuna start feeding stage.

vi. With the right feed and feeding management, Bluefin Tuna fry have showcased extremely promising growth. Below is a picture of a bluefin tuna reaching approx. 10 grams in only 7 weeks.

Bluefin Tuna juvenile at week 7 post hatch. (pictures by Thomas Hofman, (Futuna Blue) while working under supervision of Dr. Bent Urup).